This is a great series of videos, and started me down the right path.

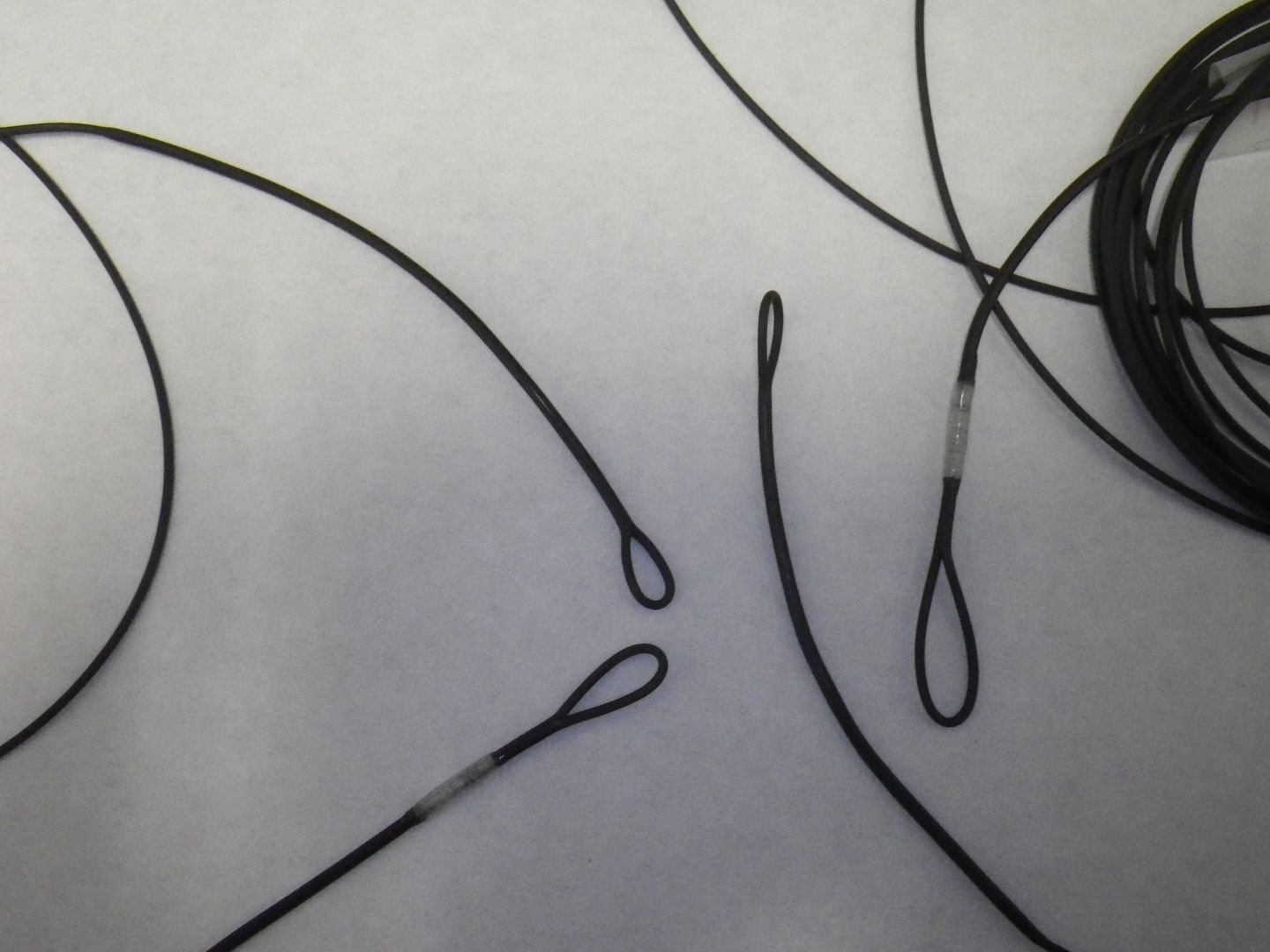

Being that I use a lot of T lines(tungsten impregnated), my first attempts were these lines. And of course, they happen to be the most difficult lines to weld.

Not all T lines are created equal. I have some generic T-11 that I cannot weld, and still have good strength. Airflo T lines weld much easier, and stay strong. Rio should weld about the same, but I have not tried it yet.

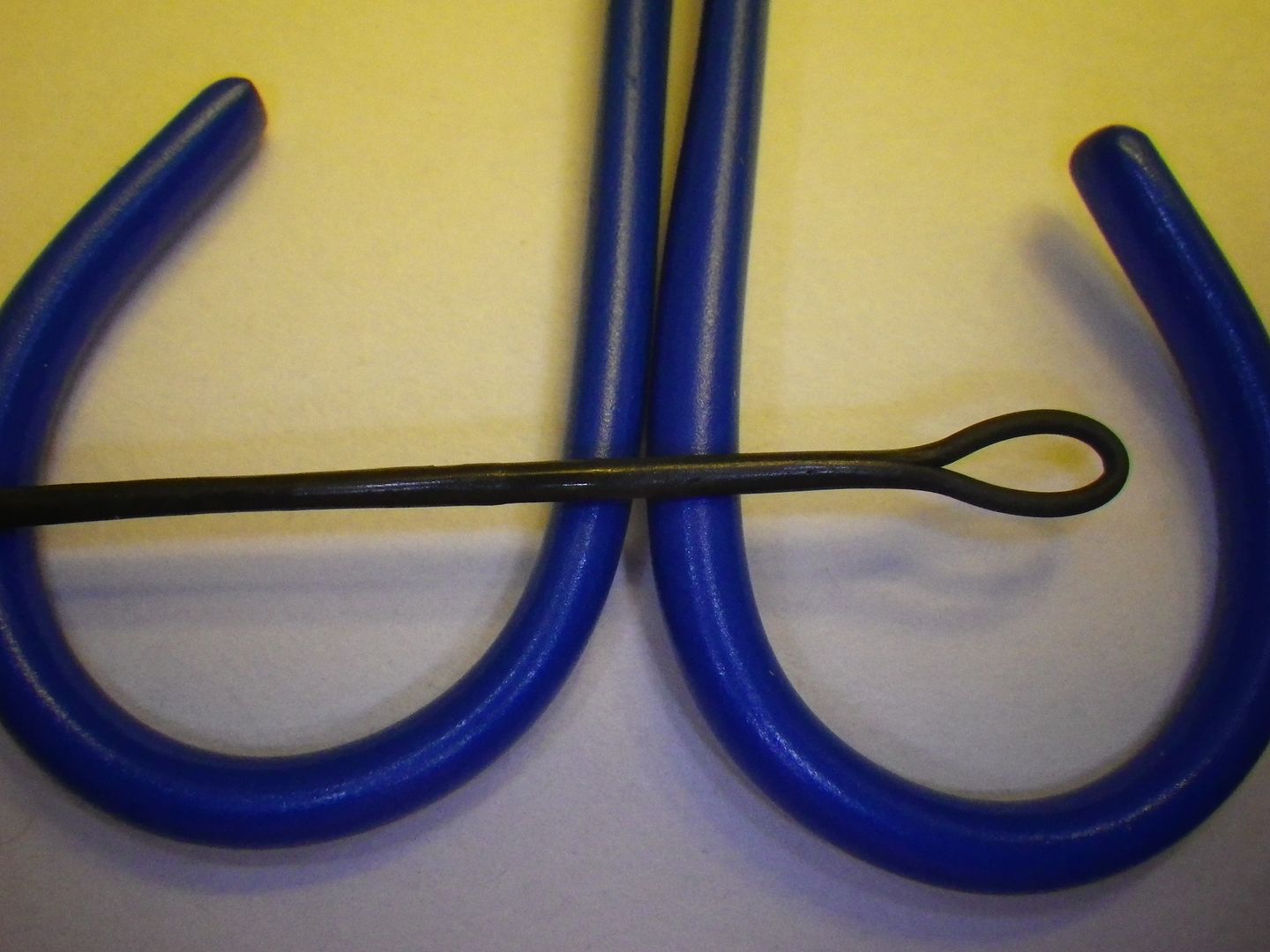

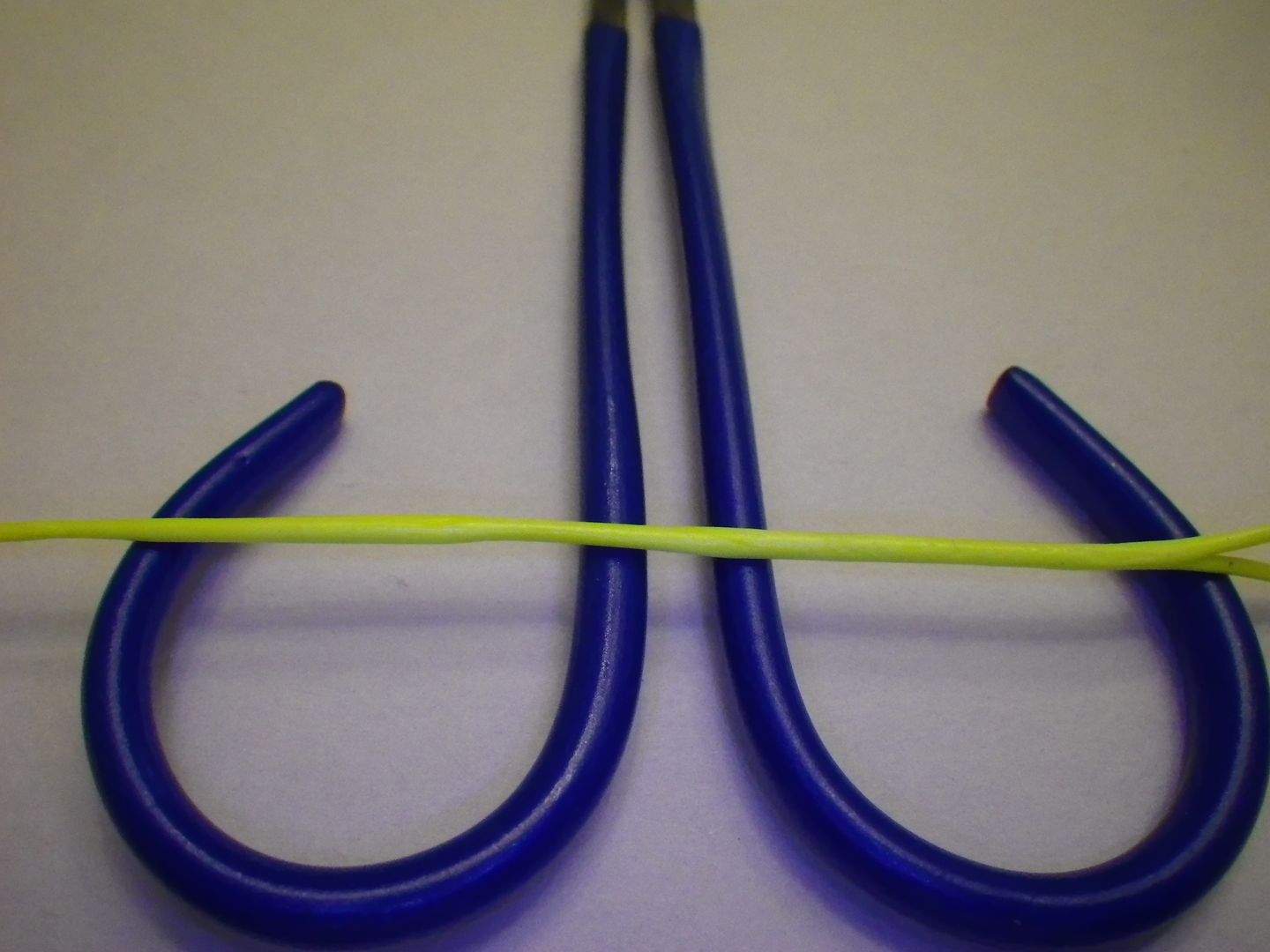

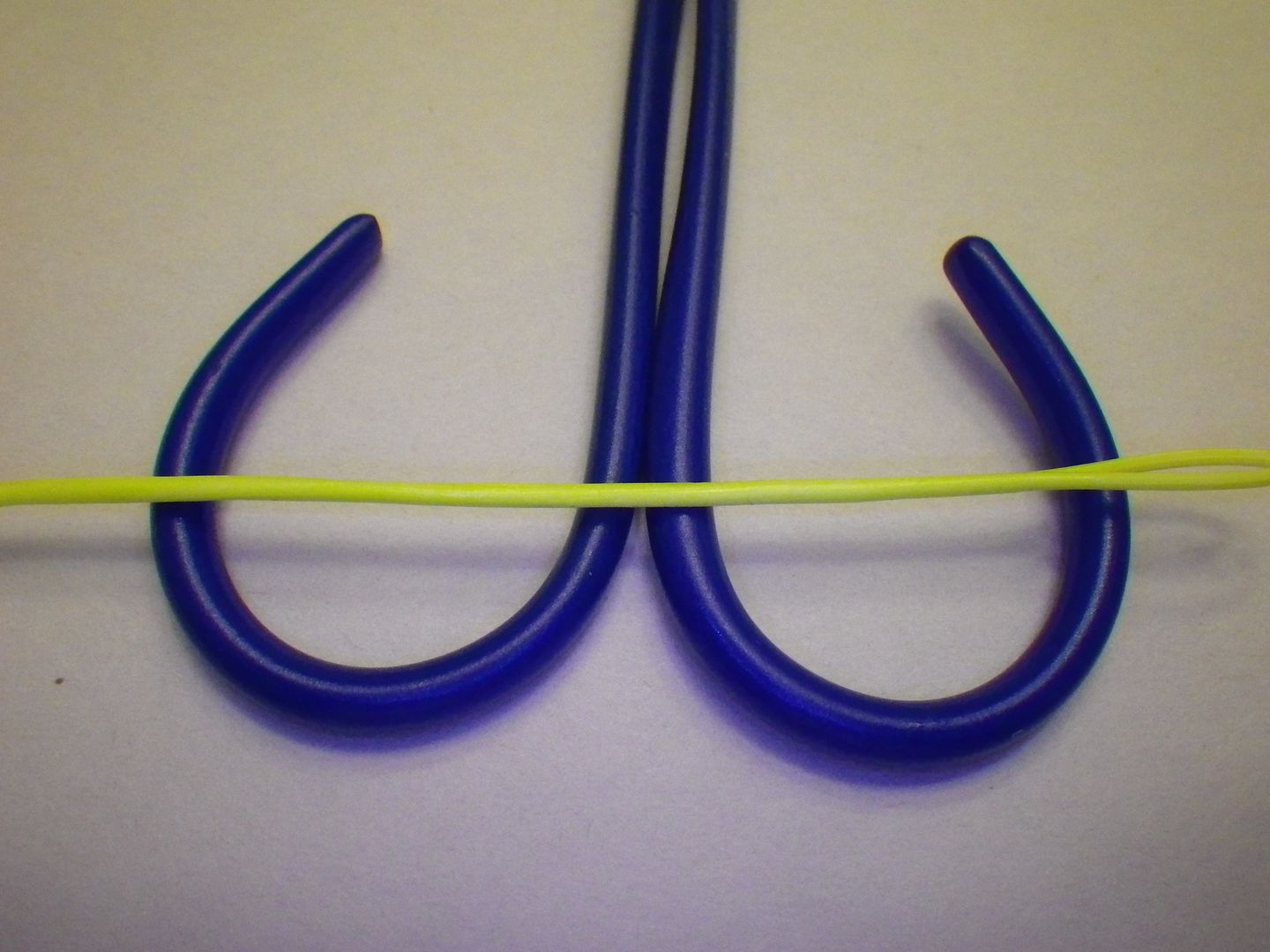

Examples

Note that you can see the seam of the two lines joined together. I think I should dial up a bit more heat, but on a pull test, it seems very strong.

I added some white tying thread to identify this line as T-14. Then I put some flexible, UV cured epoxy over it.

I've already done two, floating, running lines, and will need to do two more. At some point in the near future, more T lines will need welded loops.....plus I have a few lines I'd like to switch from braided loops, to welded loops. Easy to justify the cost if I continue to buy new, or replace old flylines.

briansII